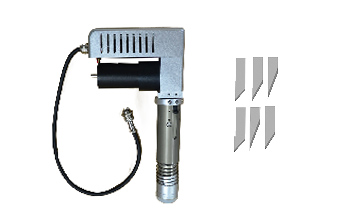

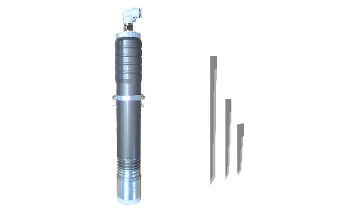

Oscillating knife cutting tool

Suitable for airtight flexible materials with a thickness of less than 18mm, such as leather, PU, PVC film materials, PVC foam board, KT board, EVA, corrugated paper, cardboard, polyester fiberboard, etc.

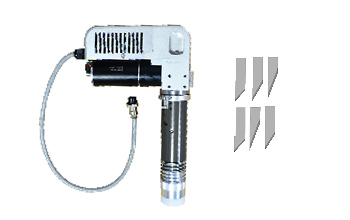

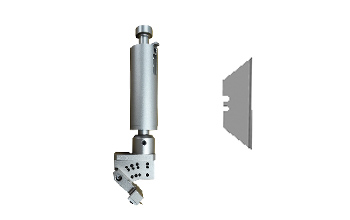

Large amplitude knife cutting tool

Suitable for some harder and thicker materials, such as asbestos sheet, graphite sheet, hard fiberboards; rubber and PVC sheet with a thickness of more than 5mm; EVA and cork with a thickness of more than 10mm, etc.

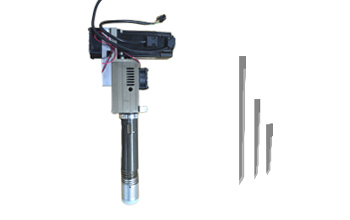

Servo knife cutting tool

Suitable for cutting some thick and hard materials such as EVA, pearl cotton, extruded board, foam, etc. with a thickness of 5-10 cm; multi-layer cutting of cloth and leather.

Pneumatic knife cutting tool

Suitable for cutting relatively thick or particularly soft foam materials, such as pearl cotton, thermal insulation cotton, sponge, rubber and plastic cotton, rock wool, EVA, honeycomb board, etc.

Driven rotary knife cutting tool

Suitable for cutting breathable material, textile materials, various woven materials, artificial wool, thin fur material, fiberglass cloth, floor mats, carpets, etc.

V-Cutting tool

Also called bevel cutter, it is used to slot some materials. It is mainly used for corrugated paper, honeycomb paper, hollow board, polyester fiberboard, rubber, EVA and other materials.

Creasing tool

It is mainly used in the packaging industry to crease the material to facilitate folding; by replacing the pressing wheel with appropriate depth and width, a perfect creasing effect can be obtained.

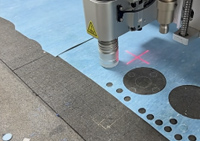

Kiss cutting tool

Suitable for cutting some self-adhesive labels and in the advertising graphic industry, car stickers, mobile phone films, protective films and other materials.

Drag knife cutting tool

It is mainly used in the advertising industry and table mat industry. It can cut PP paper, warning stickers, PVC boards with a thickness of less than one centimeter, PVC table mats, etc.

Milling tool

It can be used for cutting hard materials such as acrylic, PTFE plate, aluminum-plastic plate, density plate, etc.; as well as milling grooves of some materials.

Punching tool

The circular punch is driven by a motor to rotate at high speed to punch out smaller circular holes on the material to compensate for the non-standard small circular holes in some materials cut by the vibrating knife.

Dotted line cutting tool

Regular dotted lines are processed on the surface of some materials through Z-direction pressure, which are applied to packaging materials to facilitate tearing or folding during use.

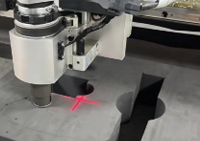

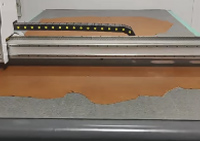

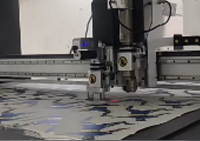

CNC Oscillating knife cutting machine can not only do these, but also can not damage the surface of the material, and will not produce smoke. It is a very good choice for the production of some gaskets with complex patterns and fine requirements. Through the calculation of materials, cnc oscillating knife cutting machine can reduce material waste and save costs during the cutting process. LOOK VIDEO>>

|

|

|

|

|

|

|

|

|

|

|

|