Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

This large-format (1600mm x 2500mm) system excels as a dedicated cnc cardboard cutter, handling standard corrugated and solid board with ease. Crucially, its high-frequency oscillating knife technology also makes it an effective honeycomb cardboard machine, cleanly processing the unique structure of honeycomb panels often used for protective packaging and lightweight structures. Featuring a versatile double knife holder equipped with both the oscillating knife and a dedicated creasing tool, it transforms into an efficient carton cutter machine, capable of producing complex box designs, prototypes, and short-run packaging orders directly from digital files with outstanding accuracy and speed.

| Parameter | ZXZ-P2516 | ZXZ-P2030 |

ZXZ-P3018 |

| Working area | L 2500mm x W 1600mm | L 2000mm x W 3000mm |

L 3000mm x W 1800mm |

| Cutting speed | 1200mm/s (Due to different materials,will affect) |

||

| Cutting toloerance | +/-0.1mm (The tolerance due to different materials) |

||

| Cutting tool | 100W/350W Oscillating knife / Creasing tool / Half-cut |

||

| Countertop type | Fixed countertop |

||

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

||

| Cutting thickness | ≤50mm (Due to different materials,will affect) |

||

| Feeding thickness | 80mm |

||

| Drive system | Servo motor / Linear guide rail / Rack |

||

| Motor | DORNA / Delta Brand |

||

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

||

| Data format | DXF / PLT / PDF / AI / OLT |

||

| Transmission interface | Ethernet |

||

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

||

| Rated power | 9kw / 11kw | ||

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent missoperation |

||

| Software | CUT / LaserCAD / ET Super nesting / JDsoft |

||

| Frame structure | Carbon dixide protected welding bed, secondary vibration aging treatment |

||

| Package | Wooden case |

||

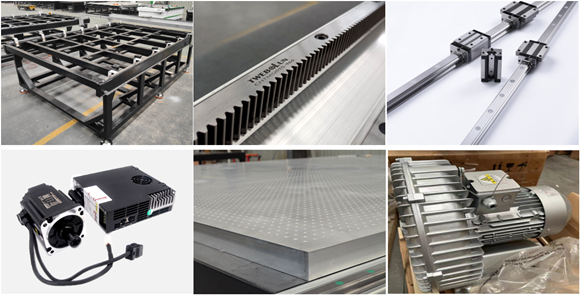

Lathe bed structure: Carbon dioxide protected welding bed, minimizes oxidation during welding. Following this, a secondary aging vibration treatment is applied, relieves internal stresses and enhances the bed's stability and precision over time.

Rack Transmission: Taiwan-imported rack brand , high-precision rack transmission system, ensuring smooth, accurate movement of the cutting head. This type of transmission is particularly beneficial for maintaining consistent cutting quality, especially in high-speed operations, as it minimizes backlash and enhances control.

Taiwan Brand Guide Rail: Linear guide rail have a sturdy construction and are designed to operate smoothly, ensuring that the cutting head moves precisely along the specified path while minimizing friction and vibration. This precision is critical to achieving clean, consistent cuts, especially in complex or intricate patterns.

Motor And Driver: Panasonic, Delta, or DORNA motors and drivers are offered as part of a CNC knife cutting machine, they play a crucial role in determining the machine's performance, accuracy, and reliability. The choice between Panasonic, Delta, or DORNA motors and drivers allows users to tailor the machine to their specific needs, balancing cost, performance, and reliability.

Adsorption Platform: Aluminum honeycomb structure provides a high strength-to-weight ratio, making the platform both lightweight and extremely durable. This ensures stability during high-speed cutting operations.vacuum suction across the platform, ensuring that the material is held firmly and uniformly. This is crucial for maintaining precision, especially when working with thin or flexible materials.

Vacuum Pump: One aviation aluminum shell fire,corrosion resistance,no rust custom energy saving model,electricity saving 30%. The silencer sponge is placed in the tube,whichcan reduce noise by 35%,100%GB pure cathode copper,20%moreexpensive than brass copper.