Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

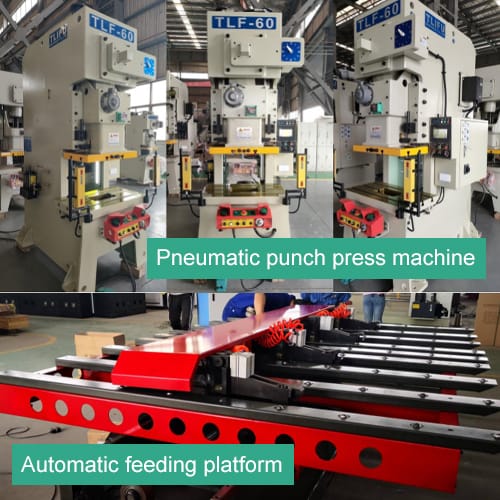

V-Type pneumatic power press machine, equipped with an automatic feeder can reduce labor and achieve the requirements of mass production of gaskets in a short time. Through automatic feeding and automatic picking, time and labor can be saved. The punch press machine has an intuitive control panel and multiple safety mechanisms to protect the operator and maintain operational reliability.

V-type crank press machine, also known as pneumatic power press machine, can achieve precise stamping, punching, and forming tasks across various industries. The crank press machine is built with a heavy-duty frame to minimize vibration and enhance cutting precision. Its intuitive controls allow for easy adjustments, accommodating a variety of materials and thicknesses to suit diverse production needs.Ideal for tasks such as gasket cutting, metal stamping, and forming, the c type press machine delivers high-speed performance without compromising on quality, helping manufacturers meet demanding production goals with confidence.

Watch how a pneumatic power press machine works on YouTube

| Serial | Name | Unit | Technical Parameters | |

| 1 | Pneumatic power press machine | --- | Open type mechanical (V type) | |

| 2 | Model | --- | TLF-60 | |

| 3 | Main Transmission Drive Model | --- | Crankshaft driven | |

| 4 | Machine Style | --- | All-in-one type | |

| 5 | Guide Rail | --- | Angular Contact Guide Rail Composed Of 6 Guide Surfaces | |

| 6 | Force Application Point | Point | 1 | |

| 7 | Ability | KN | 600 | |

| 8 | Ability Occurrence Point | MM | 4 | |

| 9 | Stroke Length | MM | 120 | |

| 10 | Slide Strokes Per Minute | Continuous Operation Mode | SPM | 35-90 |

| Intermittent Operation Mode | CPM | 65 | ||

| 11 | Closing Working Height | MM | 310 | |

| 12 | Slide Adjustment | MM | 75 | |

| 13 | Slide Size | MM | 700*400*70 | |

| 14 | Bolster Size | MM | 900*500*80 | |

| 15 | Shank Hole | MM | Φ50 | |

| 16 | Press Weight | KG | 4300 | |

| 17 | Main Motor Power | Kw*P | 5.5*4 | |

| 18 | Press Accuracy Grade |

--- | ||

| Clutch Brake | Slider Guide Rail |

| Slider And Mold Balancing Device | Overload Protection Device |

| Slider Adjustment Device | Electric Grease Lubrication System |

| Manual Thin Oil Lubrication System | Photoelectric Safety Protection Device |

| Operation Table | Air Outlet |

| Blowing Material Outlet | Mould Lighting |

| Electrical Control System | Safety Continuous Lock Function |

| Locking Operation Options |

| Serial | Parameter name | Parameter value | Unit | |

| 1 | Punching force | 600 | KN | |

| 2 | Stamping method | (See punch parameters for details) | ||

| 3 | Machine frame structure | Steel plate and profile welding | ||

| 4 | XY axis travel | 2000×1000 | MM | |

| 5 | Max processing plate | X-AXIS | 2000 | MM |

| Y-AXIS | 1000 | MM | ||

| 6 | Max thickness of processed plate | Carbon steel plate | 6 | MM |

| Stainless steel plate | 4 | MM | ||

| 7 | Clamp quantity | 4 | PCS | |

| 8 | Clamp structure | Telescopic pneumatic clamp | ||

| 9 | Number of control axes | 2(X、Y) | Axis | |

| 10 | Standard bearing strip structure | Ball bearing | ||

| 11 | Max movement speed | 32 | MM/MIN | |

| 12 | Repeat positioning accuracy | ±0.1 | MM | |

| 13 | Max load weight | 150 | KG | |

| 14 | Overall power | 4 | KW | |

| 15 | Gas source | 0.6 | Mpa | |

| 16 | Gas consumption | 150 | CL/MIN | |

| 17 | Feeder floor space dimensions (excluding punch press) | L | 1600 | MM |

| W | 2500 | MM | ||

| H | 1000 | MM | ||

| 18 | Control cabinet size | L*W*H | 600*620*1610 | MM |

| 19 | Weight | 750 | KG | |

1. The high-strength and high-rigidity body is welded with steel plates and pipes, which has strong rigidity and good stability.

2. The feeder base is welded, aged and processed as a whole, ensuring the overall accuracy; the feeding is more stable.

3. The guide rail of the longitudinal mechanism of the feeder is installed laterally, which effectively overcomes the lateral swing force and is stable and durable.

4. The precision linear rectangular guide rail ensures stability at high speed.

5. The precision large-lead ball screw has fast speed and good accuracy.

Contact us>>

Email: cutcnc@chn-rubber.com

WhatsApp: +8615222735180