Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Automatic rubber gasket making machine

Email: zxzcnc@chn-rubber.com

WhatsApp: 008618222051167

Smaller size, less floor space

|

|

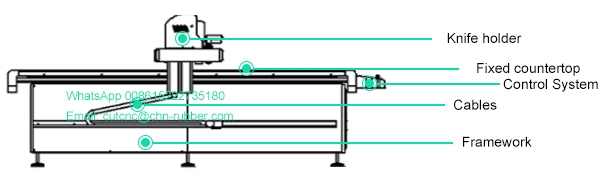

| The steel frame that has been treated with secondary vibration can minimize vibration. After long-term use, it can still maintain stability and assist in more precise cutting. | The table felt imported from the Netherlands provides a smooth and durable surface, protecting the aviation aluminum tabletop while ensuring cutting accuracy. |

|

|

| The clean and neat English operation interface ensures easy navigation and user-friendly control, enhancing efficiency and reducing the learning curve for operators. | The single modularized holder securely holds one cutting tool in place, ensuring precise and stable operation for accurate cutting results. |

900mm x 600mm rubber gasket making machine, equipped with a vibrating knife, ensures precision and efficiency in gasket production. This CNC rubber cutting machine is perfect for industrial applications, delivering high-quality and accurate results.

| Countertop type | Fixed |

| Voltage | 220+/-10% |

| Motor | DORNA |

| Cables | Germany brand IGUS |

| Tool | Vibrating knife(Low-power/High-power/Servo knife) |

| Actual cutting speed | 800 ~ 1500mm/s (Due to material thickness and hardness) |

| Effective cutting surface | 900mm x 600mm (Length*Width) |

| Control interface | 7-inch LCD touch screen |

| Guide rail | Taiwan brand |

| Supported formats | PLT/DXF/AI/PDF |

| Intelligent fault detection | Automatically detect electrical appliances when powered on and push the code to the system |

| Real-time monitoring of cutting position, you can monitor the current cutting piece and its position at any time | |

| Blade | Tungsten steel customization |

| Safety devices | Infrared blocking stop machine anti-collision protection |

When using a rubber gasket making machine, the thickness and hardness of the rubber material are critical factors. The machine settings must be adjusted to ensure accurate cutting, as well as to determine whether we can configure a more suitable tool for you based on the nature of the material you are cutting during the initial purchase, so that the best speed and accuracy can be maintained during the later cutting. Thicker or harder materials may require higher cutting power and lower speeds, while thinner or softer materials can be processed with less power and higher speeds. Proper calibration ensures that each gasket produced has clean edges and accurate dimensions.

If you need product information and product price,please contact me:

WhatsApp: 008618222051167

Email: zxzcnc@chn-rubber.com