Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

Specifically engineered as a leading automatic cutting machine in garment industry applications, this system boasts a substantial 2500mm x 1600mm cutting area, perfect for handling wide fabric lays and complex markers. It comes fully equipped with an integrated automatic feeding rack for seamless, continuous material handling directly from the roll, complemented by an extendable platform that simplifies management of long spreads and efficient offloading of cut pieces. The versatile tool head can be configured with a high-frequency vibrating knife for intricate details on delicate or stretch fabrics, a powerful circular knife for rapid cutting of heavier materials or bulk lays, and a marking pen for essential pattern annotations, delivering unparalleled precision, speed, and efficiency from raw material to finished cut parts.

| Parameter | ZXZATF1216 | ZXZATF2516 |

ZXZATF3018 |

| Working area | 1200mm x 1600mm | 2500mm x 1600mm |

3000mm x 1800mm |

| Cutting speed | 200-2000mm/s(Due to different materials,will affect) | ||

| Cutting tolerance | +/-0.1mm (The tolerance may vary due to different materials) | ||

| Cutting tool | Driven rotary cutting tool / Marking pen / Servo knife cutting tool / Pneumatic knife / Circular knife cutting tool/Oscillating knife cutting tool | ||

| Countertop type | Automatic feeding (Switch table type according to fabric size) | ||

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | ||

| Cutting thickness | 70mm | ||

| Rated Power | 9KW / 11KW | ||

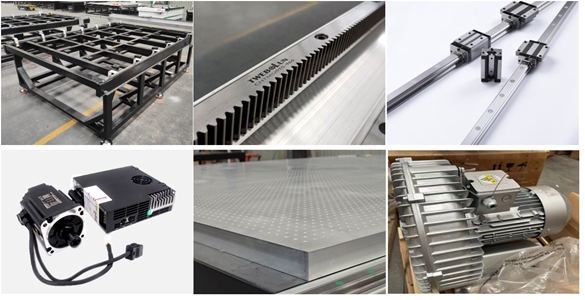

| Drive system | Servo motor, Linear guide rail, Rack | ||

| Motor | Delta Brand | ||

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation | ||

| Data Format | DXF,PLT,PDF,AI | ||

| Transmission interface | Ethernet port | ||

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system | ||

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation | ||

| Projection function | Can install projector | ||

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment | ||

| Voltage | AC 110V/220V/380V±10%, 50HZ/60HZ | ||

In addition to the core cutting and feeding functions, computerized cutting machine in garment industry can also be equipped with the following intelligent modules to further improve your production efficiency and quality:

Intelligent Nesting Software: Maximize fabric utilization and significantly reduce material costs. The software can automatically calculate the optimal piece layout plan, arrange more pieces tightly on a given width of fabric, effectively reduce scrap waste, and directly increase your profit margin. Compared with manual layout, it is faster and more efficient.

Panoramic Recognition System: Achieve accurate automatic alignment cutting of grid, stripe and printed fabrics to ensure the quality of the finished product. Through the high-definition camera scanning the fabric of the entire working area, the system can automatically identify the pattern, stripe or edge, and accurately adjust the cutting path to ensure that the pattern on the piece is perfectly aligned, avoiding the tediousness and error of manual alignment, especially suitable for the production of high-quality printed or striped clothing.

Projector System: Provides intuitive visual guidance, simplifies operation, and improves alignment and inspection efficiency. The projector can directly project the outline of the piece to be cut, the layout diagram or the alignment mark line onto the fabric. The operator can see the cutting position at a glance, which allows for quick and easy verification of layout effects, inspection of fabric defects or manual fine-tuning, improving the convenience and accuracy of operation.

Multi-Functional Tool Head: Configurable with specialized tools for diverse garment fabrics:

Applications:

The combination of automated feeding, a large cutting bed, an extendable platform, and versatile tooling makes this automatic cutting machine in garment industry applications a powerful asset for businesses aiming to optimize quality, speed, and material efficiency.