In industries that require precision cutting of exotic materials such as asbestos-free sheet, asbestos, graphite and PTFE, finding a reliable non-thermal cutting method is critical. Our CNC knife cutting machines offer an efficient, accurate and safer alternative to traditional laser and die cutting options. Designed to meet the unique needs of manufacturers working with fine and sensitive materials, ensuring clean edges, minimal waste and optimized production, without the large amounts of dust that other cutting machines produce when performing cutting tasks, machines that use blade cutting do not, and are more environmentally friendly ,safety.

Customers in industries such as gasket manufacturing, automotive, and industrial parts production often face challenges with laser and die-cutting methods when working with non-metallic materials. Here’s how our CNC knife cutting machine overcomes these issues:

Heat Sensitivity: Materials like asbestos-free sheets and PTFE are sensitive to the high temperatures generated by laser cutting. Our CNC knife cutting machine operates without heat, preserving material integrity and preventing warping or thermal damage.

Precision and Material Integrity: Maintaining edge accuracy without material distortion is critical. Our machine’s precision-driven blade provides clean cuts, ensuring consistency, even with softer or brittle materials. This means reduced waste and a finish that’s production-ready.

Versatile Material Handling: From asbestos-free and asbestos sheets to graphite and PTFE, our CNC knife cutter is tailored to handle a wide range of non-metallic materials up to 5mm thick. Its adjustable settings allow for a versatile approach to different textures and densities, enhancing efficiency across diverse material requirements.

Our CNC knife cutter is optimized for thin, flexible materials, delivering a precise cut depth control that avoids damage to even the thinnest sheets. This makes it ideal for detailed, delicate cuts that require accuracy.

Absolutely. Laser cutting can release harmful particles when working with asbestos-based materials. Our CNC knife cutter eliminates this concern by using a cold cutting method that avoids particulate release, ensuring a safer working environment.

Unlike die-cutting, which requires physical molds and can deform softer materials, the CNC knife cutting machine’s blade operates with precision and flexibility, adapting easily to material changes and specific shapes without needing new dies.

Our machine is engineered for low-maintenance operation, with durable, easy-to-replace blades. Routine checks ensure optimal performance, making it a cost-effective solution over time.

Yes, our CNC knife cutting machine is built for efficiency, supporting both small and large production volumes while maintaining high accuracy and consistency with minimal downtime.

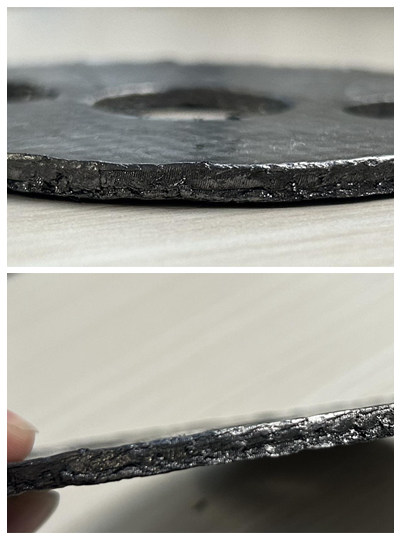

The current cutting level for PTFE and graphite can cut the edge to the best effect shown in the following pictures, without warping or burning. This level of precision is critical for products where edge quality affects performance.

Enhance your production line with a machine that’s designed for precision, power, and efficiency. Ready to see how this advanced cutter can streamline your operations? Contact us today for more details or to request a demo.

Please contact us:

Email: zxzcnc@chn-rubber.com

WhatsApp: 008618222051167