Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

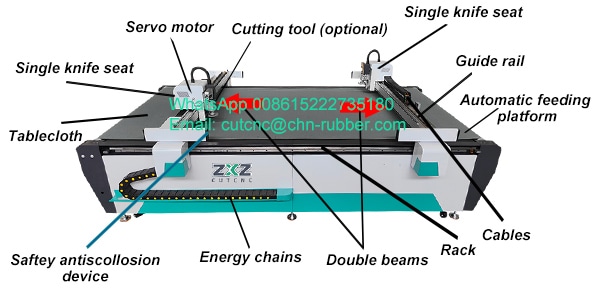

Equipped with double beams, 2 modularized cutting tool cut at the same time to improve production efficiency

Email: ctcnc@chn-rubber.com

WhatsApp: 008615222735180

CNC gasket cutting machine is equipped with automatic feeding function, which can continuously feed materials into the cutting area, simplifying the production process and significantly improving productivity, while sending the finished product off the cutting table. Especially cutting soft rubber, asbestos within 5mm, asbestos-free, graphite, etc., as well as clothing, fabrics, leather, etc., can be easily operated.

| Cutting area | 1600mm W* 2500mm L |

| Machine size | 3450mm x 2300mm x 1250mm |

| Rated power | 9KW |

| Voltage | 380V, 50HZ 60HZ |

| Cutting tool | 400W Servo knife * 1PC |

| Translational velocity | 800 - 1200mm/s |

| Cutting thickness | Asbestos, graphite within 5mm, rubber sheet 0.1mm - 30mm (depending on the hardness, thickness, etc. of the material) |

| Repeated accuracy | ≤0.1mm |

| Motor | DORNA |

| Transmission system | Digital servo motor / Linear guide / synchronous belt |

| Adsorption method | Vacuum zone adsorption |

| Power | 11KW |

| Cutting material | Fabric, Cloth, Paper, Leather, Rubber and others material |

| Resolution ratio | 0.025m |

Equipped with automatic feeding, if you are cutting 5m, 10m rolls of relatively light industrial materials, you can reduce the time and labor costs caused by manual feeding. The feeding rack can automatically complete the steps of supplying materials to the cutting platform. If it is very advantageous in mass production, but if it is a relatively heavy industrial roll of more than 15m, it is not recommended to use it because the material is too heavy. Or please contact our salesperson to provide you with more professional customization options.

|

Using a CO2-shielded welding bed, secondary vibration aging treatment, this vibration redistributes residual stresses within the material, preventing warping, deformation or cracking over time. Long welding life. |

|

With two modularized cutting tools operating simultaneously, it is designed to significantly increase cutting efficiency and productivity. By incorporating two independent cutting heads that can work in parallel, the system can cut a single workpiece or two independent areas simultaneously, effectively doubling output compared to a single-tool setup. |

Each cutting tool can often be controlled independently, allowing the flexibility to cut different shapes, sizes or patterns on the same material, or process two different parts of a large workpiece simultaneously.

WhatsApp: 008615222735180

Email: cutcnc@chn-rubber.com