Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

CNC oscillating knife cutting machine high power

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

400W High power servo motor vibrating knife

Choosing a CNC oscillating knife cutting machine offers unparalleled versatility and precision for a wide range of cutting applications. These machines excel in handling both soft and semi-rigid materials, providing clean, accurate cuts that minimize waste and reduce post-processing time. The oscillating knife's rapid, controlled motion ensures detailed and intricate patterns can be cut with ease, making it ideal for industries such as textiles, automotive, packaging, and composites. Additionally, the automation and programmable nature of CNC systems streamline production, enhancing efficiency and consistency while reducing manual labor and operational costs. This combination of advanced technology and operational flexibility makes cnc oscillating knife cutting machine a superior choice for modern manufacturing needs.

In the gasket industry, gasket sheet cutter has become an increasingly popular trend.

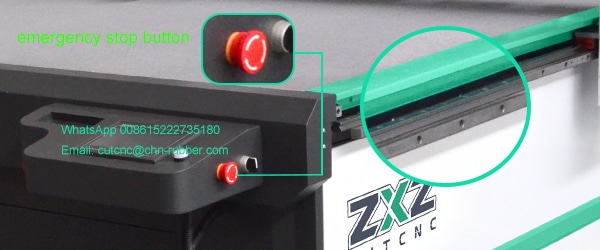

The emergency stop button installed on the gasket sheet cutter is a very important safety feature. If an emergency occurs at work and it poses a danger to the operator or other personnel, the emergency stop button can be quickly pressed. It will disconnect the power supply of the machine's moving parts and stop all cutting and movement activities immediately. This is why the button is placed in a conspicuous position on the gasket sheet cutter. This feature helps prevent accidents, injuries, and damage to the machine or materials being processed. Quick response in dangerous situations improves work safety standards.

| Technical parameters | Specifications |

| Effective cutting length | 2500mm |

| Effective cutting width | 1600mm |

| Countertop Type | Fixed (Feed-type countertops can be customized if required) |

| Actual cutting speed | 10-1300mm/s (depending on the material) |

| adsorption mode | Vacuum adsorption platform, partition/follow-up adsorption |

| Tool | Servo vibrating knife *1PC |

| Cutting tablecloth | 4MM high strength felt (depending on the situation) |

| Motor | DORNA / Panasonic / Delta |

| Cables | German imported brand |

| Gear rack | Taiwan Brand |

| Control System | Standard configuration English system (multi-language system can be customized) |

| Intelligent fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Remote error diagnosis | You can choose to solve the problem remotely based on the customer's wishes. |

| Framework | Carbon dioxide protected welding bed, secondary vibration aging treatment |

| Warranty | 1 Year |

Vibrating knives equipped with servo motors can control blade movement more accurately than ordinary vibrating knives, ensuring high-precision cutting of products and uniform cutting throughout the process. The vibration marks of the products are almost invisible. In addition, this servo knife can cut a wider range of material thicknesses. Precise control and automation functions can increase cutting speed and improve overall efficiency. However, ordinary vibrating knives cannot achieve the same level of accuracy as servo knives when cutting some super complex and relatively hard materials, and the speed is also slower.

Contact us:

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180