Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

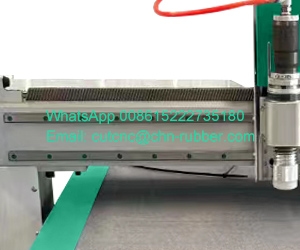

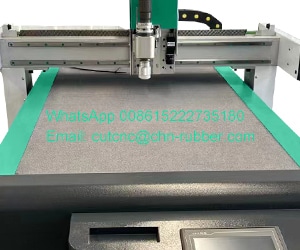

Small size gasket cutting machine

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180(mobile)

Size 900mm x 600mm

| Feature | 900mm x 600mm | 2500mm x 1600mm |

| Size | 900mm (length) x 600mm (width) | 2500mm (length) x 1600mm (width) |

| Area | Smaller, more compact | Larger, requires more space |

| Applications | Suitable for smaller-scale projects and workshops with limited space | Ideal for large-scale projects and industrial applications |

| Advantages | Space-efficient, easier to handle, versatile for smaller jobs, cost-effective, easier maintenance, lower energy consumption | Larger cutting area, capable of handling bigger projects and materials |

| Limitations | Limited cutting area, not suitable for large-scale projects | Requires more space, more challenging to handle and install |

The sizie 900mm x 600mm gasket making machine is advantageous for businesses and workshops that require a compact, cost-effective, and versatile cutting solution. It’s perfect for smaller projects and environments where space and budget are constrained. In contrast, the 2500mm x 1600mm size is suited for large-scale industrial applications where a larger cutting area is necessary.

| Type | CNC Gasket making machine |

| Working area | 900mm x 600mm |

| Adsorption method | Zoned adsorption |

| Voltage | 380V+/-10% |

| Motor | DORNA |

| Tool | Vibrating knife |

| File type | DXF/PLT/PDF/AI |

| Countertop Type | Fixed countertop |

| Actual cutting speed | 10-1300mm/s (depending on the material) |

| Framework | Heavy steel welded bed, secondary vibration aging treatment |

| Cables | IGUS |

| Safety devices | Infrared blocking stop and anti-collision protection |

| Interface | Internet port/wireless transmission |

|

|

|

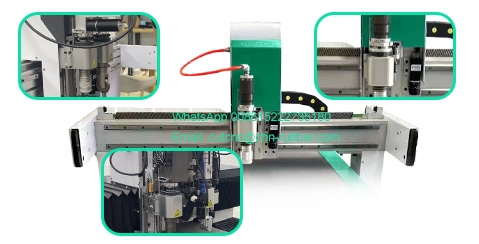

| Knife Holder | Guide Rail | |

| The knife holder securely positions the cutting blade, ensuring precise alignment and stability during operation, which is essential for achieving accurate and clean cuts." | The guide rail ensures precise and stable linear movement, enhancing the cutting accuracy and operational smoothness, essential for achieving high-quality results. | |

|

|

|

| Crossbeam | Control System | |

| The crossbeam ensures structural stability and precise alignment, enhancing the machine's accuracy and performance during cutting operations. | The control system offers intuitive and precise operation, enabling easy adjustments and seamless management of cutting processes for optimal efficiency and accuracy. |

This gasket making machine can still be configured with ordinary vibration knife, high-power vibration knife, and servo knife to complete most of the gasket cutting requirements.

Please contact us:

Email: cutcnc@chn-rubber.com

WhatsApp:008615222735180