Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

Transform your apparel production with our next-generation cnc clothing machine, engineered for unparalleled accuracy and automation. This system features an expansive 2500mm x 1600mm cutting surface combined with a seamless automatic feeding rack, enabling continuous processing of fabric rolls. Sophisticated nesting software works intelligently to optimize pattern layouts, dramatically reducing material waste – a crucial factor in profitable garment manufacturing. Precision alignment, even on complex prints or stretch fabrics, is guaranteed through the advanced visual suite, integrating projection guidance with large-format CCD panoramic positioning. As a highly efficient cnc cloth cutting machine, its adaptable tooling system, configurable with vibrating knives for intricate details, circular knives for rapid cutting of various textiles, and marking pens for essential annotations, delivers consistently clean results. This integrated solution defines the modern cloth cutting machine automatic, streamlining your entire cutting workflow from digital pattern to perfectly cut pieces ready for sewing.

| Parameter | ZXZATF2516 | ZXZATF3018 |

| Working area | 2500mm x 1600mm | 3000mm x 1800mm |

| Cutting speed | 200-2000mm/s(Due to different materials,will affect) | |

| Cutting tolerance | +/-0.1mm (The tolerance may vary due to different materials) | |

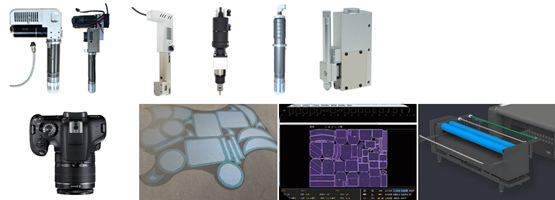

| Cutting tool | Driven rotary cutting tool / Marking pen / Servo knife cutting tool / Pneumatic knife / Circular knife cutting tool/Oscillating knife cutting tool | |

| Countertop type | Automatic feeding | |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | |

| Cutting thickness | 70mm | |

| Rated Power | 11KW | |

| Drive system | Servo motor, Linear guide rail, Rack | |

| Motor | Delta | |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation | |

| Data Format | DXF,PLT,PDF,AI | |

| Transmission interface | Ethernet port | |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system | |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation | |

| Projection function | Can install projector | |

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment | |

| Voltage | AC 220V/380V±10%, 50HZ/60HZ | |

Adaptable Tooling for Textiles: Configurable head supports: