Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

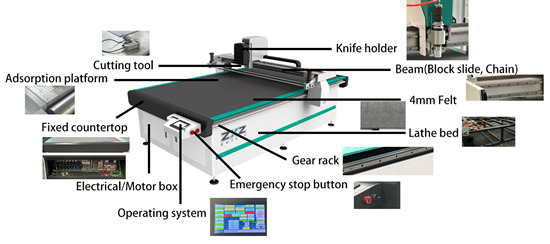

Acoustic panel cutting machine redefines precision and efficiency in shaping sound-absorbing materials. Engineered for both small workshops and high-volume production lines, it combines a rock-solid welded-steel frame with ultra-accurate linear guides to eliminate vibration and chatter. Its intelligent control system adapts blade speed and pressure in real time—whether you’re cutting soft acoustic foam, dense mineral wool, or multi-layer composites—ensuring every edge is clean, consistent, and ready for assembly. With integrated dust extraction and an intuitive touchscreen, operators can load CAD or PDF files in seconds, monitor progress live, and switch tooling at will, all while maintaining a quiet, safe work environment.

| Parameter | #2516 Machine |

| Working area | L 2500mm x W 1600mm |

| Cutting speed | 1200mm/s (Due to different materials,will affect) |

| Cutting toloerance | +/-0.1mm (The tolerance due to different materials) |

| Cutting tool | 100W Oscillating knife / Creasing tool / Half-cut / CCD / Round knife |

| Countertop type | Automatic feeding |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤50mm (Due to different materials,will affect) |

| Feeding thickness | 120mm |

| Drive system | Servo motor / Linear guide rail / Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data format | DXF / PLT / PDF / AI |

| Transmission interface | Ethernet |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent missoperation |

| Software | CUT / LaserCAD / ET Super nesting / JDsoft |

| Frame structure | Carbon dixide protected welding bed, secondary vibration aging treatment |

| Package | Wooden case |