Traditional packagng cutting machines require manual feeding, long mold change time, large cutting errors, difficult cutting of complex graphics, and easy waste of materials. Small batch orders are prone to losing customers, and are also prone to losing some personalized, high value-added product orders. The vibration knife increases the rotation speed, adds nesting software, and can also add an automatic feeding platform. The servo motor increases the cutting accuracy by +/-0.2mm. Using various cutting tools, it can complete multiple tasks such as cutting, creasing, punching, etc. The qualified rate of finished products is increased to 95%, reducing labor costs.

|

|

|

|

|

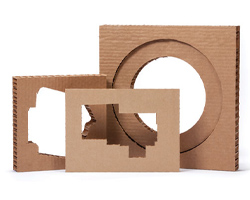

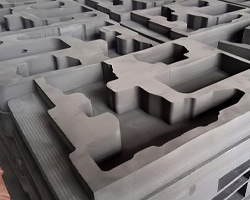

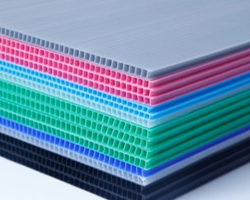

In the packaging industry, vibrating knife cutting machines are widely used in the processing of cartons, foam, honeycomb panels, plastic panels, corrugated paper, leather packaging and other materials. Suitable for production needs such as customized packaging, cushioning lining, display packaging, etc. Applicable materials

Grey Board / White Card Paper / Corrugated Board / Honeycomb Cardboard / Coated Paper

EVA foam / Expanded Polyethylene / XPE/IXPE foam material / Polyurethane Foam / Sponge

PP Hollow Sheet

Honeycomb Board / Kraft Paper Composite

PU Leather / Genuine Leather / Flocked Fabric

The vibrating knife cutting machine provides the packaging industry with efficient, intelligent and refined processing solutions, especially suitable for the production and manufacturing of high-end packaging, customized packaging and industrial protective packaging.

|

|

|

|

|

|